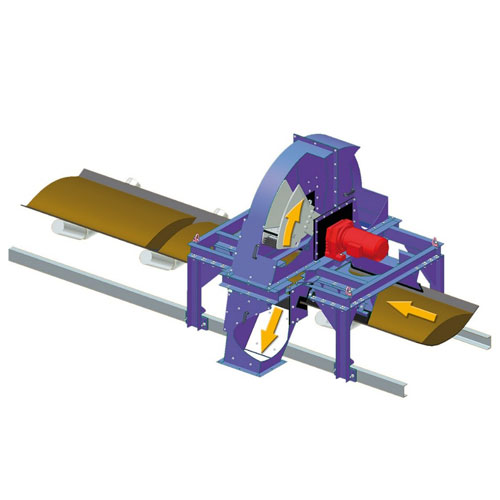

Cross Belt Sampler

The Cross Belt Sampler obtains a representative sample of granular materials directly from a moving trough-belt type conveyor. The unit has a single direction motion which sweeps the belt clean and discharges the materials into a fixed type collection chute positioned at the side of the trough belt conveyor. The Cross Belt Sampler comprises a sample cutter attached to a drive shaft carried in bearings which are mounted on a channel section base frame. This is positioned directly above the trough belt conveyor. The base frame is usually fixed onto a support structure anchored at the local floor level or to the conveyor stringers.

- Can be installed for sampling of coal, coke, copper, precious metals, salt, sand, stone, gravel, iron ore and other bulk materials

Idler trough angles between 20° to 38°

Suits belts from 450 mm to 2500 mm wide

Suit up to belt speed of 6mtr/sec

Durable stainless or Mn steel sample cutter scoop design

Computer generated design models in inventor for correct sampling

New skew cutter designs to reduce material disturbance and eliminate spillage

PLC / Timer based control panel to operate the equipment automatic/ Semi-automatically

Cost-effective sampling solution

Easier to install than other sampling equipment offerings

Incorporates the belt contouring system for correct sample extraction

Multiple duty class designs are available, including standard-duty, heavy-duty and extreme-duty

Designs suitable up to 10,000 tph are available

- Standard electro-mechanical drives and brakes with other heavy-duty drive and braking options are available

Multiple access ports to inspect and maintain all working components

Robust design intended for long-term reliability in harsh applications

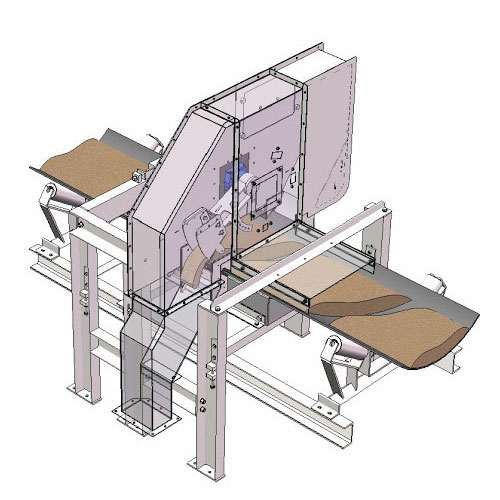

The REE Conventional Cross Stream Sampler is custom designed to be an integral part of the main conveyor head chute which meets the client’s specific requirements. The Cross Stream sampler is typically installed in new applications where large primary sample increments are required or space limitations exist prohibiting the installation of a Rotary Sweep Sampler along the conveyor. The REE Cross Stream Sampler is available with either an electro-mechanical drive mechanism.

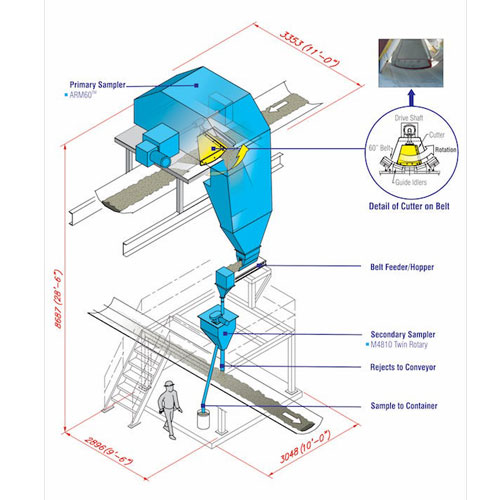

2-Stage Sampling System:

The 2-Stage Sampling System is the most common system arrangement. It includes a sealed primary sample receiving chute, primary belt feeder, sample crusher, secondary sampler, sample collector and reject handling system (Screw Conveyor, Belt Feeder or Bucket Elevator).

The primary belt feeder feeds the primary sample increments to the sample crusher where the sample increments are typically reduced to a 4-mesh product. The product from the crusher is gravity fed to a Belt Feeder where the secondary sampler is installed and it eventually takes a secondary increment. The secondary increment is gravity fed and saved in a sample container. The reject handling system returns the reject to the main conveyor for most installations.

3-Stage Sampling System

The 3-Stage Sampling System is typically utilized with the Conventional Cross Stream Sampler which produces a very large primary sample increment and requires an additional stage of processing to reduce the sample to a manageable size. This arrangement includes a sealed primary sample receiving hopper, primary belt feeder, secondary sampler, secondary feeder, sample crusher, tertiary sampler, sample collector and reject handling system.

The primary belt feeder feeds the primary sample increments to the secondary sampler. The secondary sample increments are fed via the secondary feeder to the sample crusher where the sample increments are typically reduced to a 4-mesh product. The product from the crusher is gravity fed to a tertiary sampler which takes a tertiary increment. The tertiary increment is gravity fed and saved in a sample container. The reject handling system returns the reject from the secondary sampler and tertiary sampler to the main conveyor for most installations.